Fertilizer granulators have become an essential tool for agriculture, as they offer a convenient and efficient way to produce high-quality granulated fertilizers. In this article, we will discuss the benefits of using a fertilizer granulator, the different types of granulators available, and the factors to consider when choosing a fertilizer granulator.

Types of Fertilizer Granulators

There are several types of fertilizer granulators available on the market, each with its advantages and disadvantages. The most common types of fertilizer granulators are:

- Rotary Drum Granulators: These are large, cylindrical drums that rotate to produce granules. They are suitable for large-scale production and produce high-quality granules.

- Disc Granulators: These machines use a rotating disc to produce granules. They are suitable for small and medium-scale production and produce uniform granules.

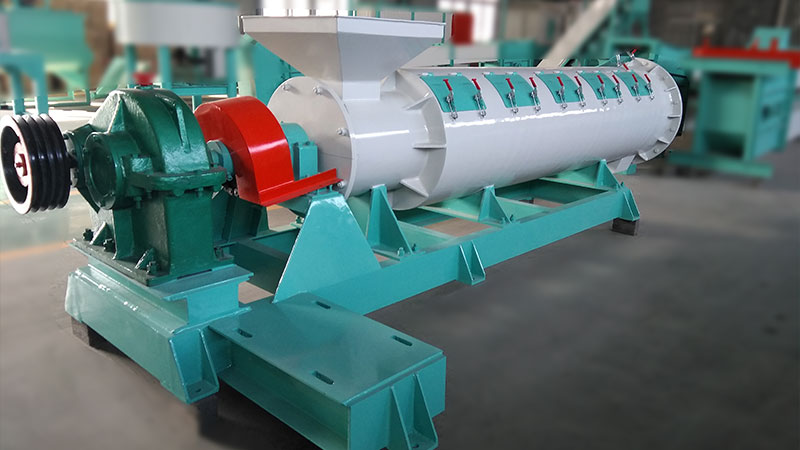

- Double Roller Extrusion Granulators: These machines use two rollers to press powder into granules. They are suitable for small-scale production and produce dense, round granules.

- Flat Die Extrusion Granulators: These machines use a flat die to extrude powder into granules. They are suitable for small-scale production and produce high-quality granules.

How Fertilizer Granulators Work Fertilizer granulators work by using a combination of moisture, pressure, and rolling motion to form granules from powder. The key components of a fertilizer granulator include a feeding system, a granulating chamber, and a discharge system.

Benefits of Using a Fertilizer Granulator

Using a fertilizer granulator has several benefits, including:

- Environmental Benefits: Granulated fertilizers release nutrients slowly, reducing the risk of over-fertilization and pollution of soil and water.

- Economic Benefits: Using granulated fertilizers can improve crop yields and reduce the need for chemical fertilizers, saving money in the long run.

- Health Benefits: Granulated fertilizers are safer for humans, pets, and wildlife than chemical fertilizers.

Factors to Consider When Choosing a Fertilizer Granulator

When choosing a fertilizer granulator, there are several factors to consider, including:

- Size of the Granulator and Capacity: The size of the granulator should be appropriate for the amount of fertilizer you need to produce.

- Energy Efficiency and Power Source: Consider the energy efficiency and power source of the granulator, as this can affect its cost and environmental impact.

- Ease of Use and Maintenance: Choose a granulator that is easy to use and maintain, as this will save you time and effort in the long run.

- Price and Budget Considerations: Fertilizer granulators vary in price, so consider your budget before making a purchase.

Conclusion Fertilizer granulators have become an essential tool for agriculture, as they offer a convenient and efficient way to produce high-quality granulated fertilizers. By choosing the right fertilizer granulator, you can enjoy the benefits of granulated fertilizers without the hassle of traditional methods. Consider the factors discussed in this article when choosing a fertilizer granulator and start enjoying the benefits of granulated fertilizers today.